Our mission is to provide people around the World with high quality, low energy and resource saving illumination products. All made for specific purposes. Our tools are color mixing, optics and design. And our target groups range from the few hundred people to millions, depending on the product.

/Dan Friis

Dan Friis CEO Denmark

News:

As we have expanded with many new activities, time has come to restructure these activities. In future, RGB-Lamps, will mainly be a recearch and development business.

When new products and services are ready for sales, they will be put in separated new businesses for further development, production and sales. Only very specialiced products like the Porphyria Bulb will be sold directly from this company. RGB-Lamps will act as web-host until each separated activity has it's own web-site. While the sites are being updated, some information will be missing. We will try to do the update and implement the changes as fast as possible.

Oct.2016

Contact:

RGB-Lamps.com

Skelbyvej 8

4874 Gedser

Denmark

CVR: 12744994

info@rgb-lamps.com

webmaster@rgb-lamps.com

exports@rgb-lamps.com

dan.friis@rgb-lamps.com

Phone:

+45 32 13 74 74

We are creating illumination for you.

Mixing colors is an art, and we are the best.

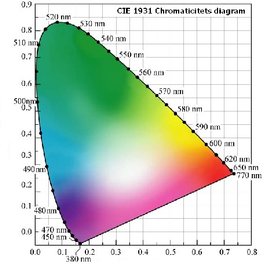

When we are making a new mixed bulb, we first have to determine the

color by Means of the chromaticity diagram. And after that, we have to

calculate the ratio of diodes. That sounds easy but it is not, since every

wavelength of light has it's own energy content. When mixing a bulb

that contains 7 different colors, it takes more than 50.000 calculations

to design the bulb.

When the design is ready, the manufacturing takes start. The diode part

and the power supply are assembled according to the result of the design

process, and is finally combined before it is put in a plastic Shell designed

by our self.

Plastic Shells are made in polycarbonate, to make it strong and fire resistant.

Then we attach a socket. Above you can see bulbs with the small E14 and

the large E27 screw. Our bulbs are made with brass screws, since they

have to last for many years of use. Plated screws will cause trouble after

few years of use, dependent on the air humidity in the place it is used.

The surface oxydates and becomes insulating. That does not happen with

our brass Edison screws.

Then a diffusing lens is attached to the bulb. And to protect the bulb

and the lens against damage, in case it is dropped, we are using a

siliconrubber sealing.

Last part before shipping, is the testing and marking of each bulb.

Our bulbs are made in accordance with the European CE rules, that

ensures a safe product, that will not interfere with other electrical

equipment.

These bulbs and the technoloy behind, can be used in a

variety of products. Ranging from ordinary illumination, to plant

growth and special products for patients suffering form diseases,

making them sensitive to certain illumination spectres.

Chromaticity diagram used for selection of diodes.

Production tool for the siliconrubber ring.

Visit our Associated web-sites: