Vores mission er at fremstille og sælge energirigtige og resourcebesparende belysningsprodukter i høj kvalitet, til kunder over hele verden. Vores LED teknologi har i Danmark vundet flere priser, og er blandt verdens absolut bedste.

/Dan Friis

Dan Friis CEO Denmark

Nyt:

TrueColors er kommet godt fra start i Filippinerne, og vi satser nu på at få introduceret vores nye designs, baseret på Filippinsk marmor og dansk teknologi.

Vi går nu i gang med et crowdfunding projekt, der skal finansiere flere butikker og en lang række nye produkter.

Aug.2015

We are creating illumination for you.

Mixing colors is an art, and we are the best.

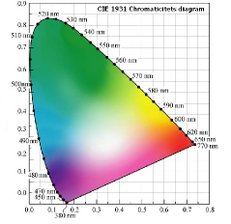

When we are making a new mixed bulb, we first have to determine the

color by Means of the chromaticity diagram. And after that, we have to

calculate the ratio of diodes. That sounds easy but it is not, since every

wavelength of light has it's own energy content. When mixing a bulb

that contains 7 different colors, it takes more than 50.000 calculations

to design the bulb.

When the design is ready, the manufacturing takes start. The diode part

and the power supply are assembled according to the result of the design

process, and is finally combined before it is put in a plastic Shell designed

by our self.

Plastic Shells are made in polycarbonate, to make it strong and fire resistant.

Then we attach a socket. Above you can see bulbs with the small E14 and

the large E27 screw. Our bulbs are made with brass screws, since they

have to last for many years of use. Plated screws will cause trouble after

few years of use, dependent on the air humidity in the place it is used.

The surface oxydates and becomes insulating. That does not happen with

our brass Edison screws.

Then a diffusing lens is attached to the bulb. And to protect the bulb

and the lens against damage, in case it is dropped, we are using a

siliconrubber sealing.

Last part before shipping, is the testing and marking of each bulb.

Our bulbs are made in accordance with the European CE rules, that

ensures a safe product, that will not interfere with other electrical

equipment.

Bulbs are put in the lamps in the shops, which ensures a final check

that both bulb and lamp is in perfect condition, when it is sold to

our custumers.

Production tool for the siliconrubber ring.

Chromaticity diagram used for selection of diodes.

Contact:

RGB-Lamps.com

Skelbyvej 8

4874 Gedser

Denmark

CVR: 12744994

info@rgb-lamps.com

webmaster@rgb-lamps.com

exports@rgb-lamps.com

dan.friis@rgb-lamps.com

Phone:

+45 32 13 74 74

Besøg vores tilknyttede web-sites: